My work is multidisciplinary and practice-based, involving interaction/experience design, graphic/visual communication design, new media/installation art, and industrial design. Over the course of my career in academia, I have developed a non-traditional approach to scholarship, favoring user-centered research that directly benefits individuals and manifests as beneficial effects on people. I believe applied creativity, as a personal practice and intention to affect others, has the potential to make a positive impact on people’s lives. Over the last ten years, I have worked across many media; I see technology as a creative tool both for the designer and the user.

RECENT NEWS

The wonderful people at TechOWL (Pennsylvania’s Assistive Technology Act program) in Philadelphia posted about the PushnDraw® on instagram.

I am so excited to have been awarded a Maggie E. Neumann Research Grant! (College of Health Sciences, University of Delaware) for “User-Centered Design Methods in the Development of an Assistive Drawing Device-Software System for individuals with Upper Extremity Motor Disabilities.” This is a collaboration with Adam Wickenheiser (Mechanical Engineering), and Michele Lobo (Physical Therapy). We are currently seeking participants for this study. More info at https://pushndraw.com/participate

Another great UDaily article about my work and crowdfunding efforts to support it, “Delaware First: Changing Lives Together.” (March 08, 2022).

Very thriled to have received a Research/Creative Activities Grant from the Engagement Scholarship Consortium, “Helping AMC Families with Assistive Devices.”

I enjoyed presenting the Type Play Project at TypeCon 2021. (October 23, 2021). This is one of my favorite assignments.

Honored to receive an NSF-funded I-Corps Sites MVP grant from UD’s Horn Entrepreneurship to facilitate customer discovery and prototype development of the PushnDraw®.

VIDEOS FEATURING MY RESEARCH & RECORDED LECTURES

UD IxD Lab Tackles Physical Disabilities Challenges

Aug 5, 2020 // Newark, DelawareThe Interaction Design Lab at the University of Delaware develops assistive devices for kids and adults with different physical disabilities. Ashley Pigford, co-director of the lab, applied his graphic design and interaction design background to an area that matters to the world, empowering individuals and caregivers through the lab’s creations.

Teaching Physical Computing in IxD Curricula

@ IxDA20 Design Education Summit

Feb 3, 2020 // Milan, ItalyThis is a presentation of a course curriculum I have developed over the last ten years that takes students from an introduction to electronics to the design and fabrication of interactive experiences.

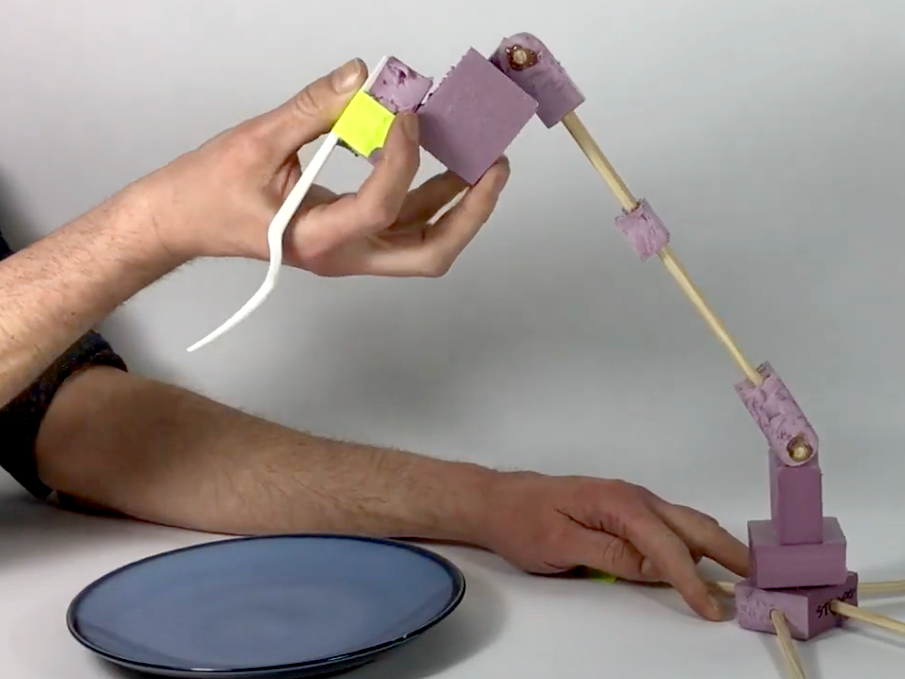

Adaptive Technology: From D.I.Y. to Low-Cost Robotic Solutions to Independent Eating @ AMCSI

July 5, 2019 // Norfolk, VirginiaAshley Pigford and Tracy Shank - Adaptive Technology: From D.I.Y. to Low-Cost Robotic Solutions to Independent Eating. (Starts at 1:58)

Technology as Generative Tools @ University of Wisconsin

May 27, 2016 // Milwaukee, WisconsinZoom Milwaukee was a 4-day symposium on craft and innovation hosted by the University of Wisconsin Milwaukee’s Jewelry and Metalsmithing program. Over 250 makers, writers, and innovators came together to discuss the future of craft in 10 lectures and 27 workshops. The Chipstone Foundation was a proud sponsor of the Zoom symposium.

Creating Interdisciplinary Knowledge Through Community Engagement

September 26, 2016 // Newark, DelawareNew Connections: Creating Interdisciplinary Knowledge Through Community Engagement" ISLL Speaker Series at the University of Delaware.

Learning the Strokes: Teaching Typography through Lettering @ ATypI 2016

October 25, 2016 // Warsaw, PolandThis presentation outlines the process I have found successful, (and very enjoyable), to initiate the study of typography in my Typography 1 course, by starting with hand lettering.

Drawing Machines @ Tasmeem Doha Hybrid Making 2013

April 4, 2013 // Doha, QatarDocumentation of Lab Golf, led by Ashley John Pigford. Video by Abir Zakzok, Hana Al Saadi, and Maeda Al Haidar, as part of Lab Mike, led by Simone Muscolino, Jorell Legaspi and Jordan Gushwa @ Virginia Commonwealth University in Qatar.

Translationships @ Living Arts of Tulsa

June 12, 2012 // Tulsa, OklahomaAshley John Pigford's artist talk on June 1, 2012 at LivingArtSpace. This talk describes my process and many of the works in this solo exhibition.

Vista Sans Wood Type Project @ AIGA Philly SPACE

October 5, 2012 // Philadelphia, PennsylvaniaTricia Treacy and Ashley Pigford gave an informal talk about the Vista Sans Wood Type Project at the opening of an exhibition of the project at AIGA Philadelphia's SPACE gallery on October 5, 2012.

Spin, Click, Knock @ Urban Institute of Contemporary Art

March 5, 2010 // Grand Rapids, MichiganAshley John Pigford discusses his work entitled Spin, Click, Knock, exhibited in his solo exhibition at UICA from February 5 to March 5, 2010.

Meet the Artist @ Delaware Division of the Arts

October, 2010 // Wilmington, DelawareAshley Pigford describes his process and many of the works in his solo exhibition, “Collective Conscious,” at the Mezzanine Gallery in Wilmington, Delaware. This was in conjunction with his fellowship in sculpture, awarded by the State of Delaware.